Shop by Category: > All Categories

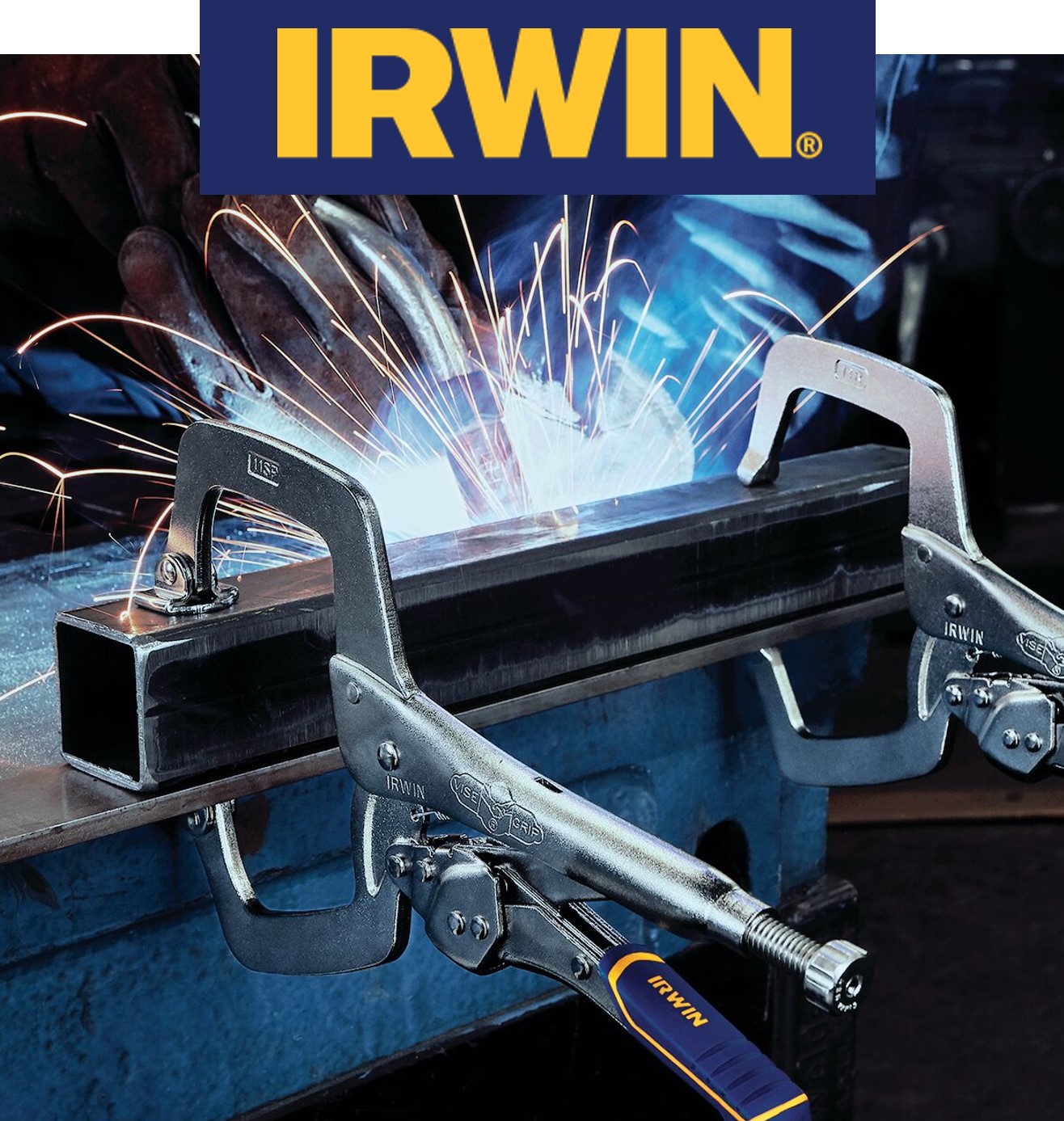

Clamps

Cutting & Crimping Tools

Drywall & Plastering Tools

Files

Hammers & Striking Tools

Hand Saws & Accessories

Hand Tool Kits

Impact Sockets & Bits

Inspection & Retrieving Tools

Marking Tools

Masonry, Concrete & Tile Tools

Pliers

Plumbing Tools

Prying Tools

Punches, Chisels & Hand Drills

Screwdrivers & Nutdrivers

Sockets & Bits

Specialty Tools

Staplers & Staple Pullers

Tool Storage & Transfer Tanks

Vises & Accessories

Wrenches

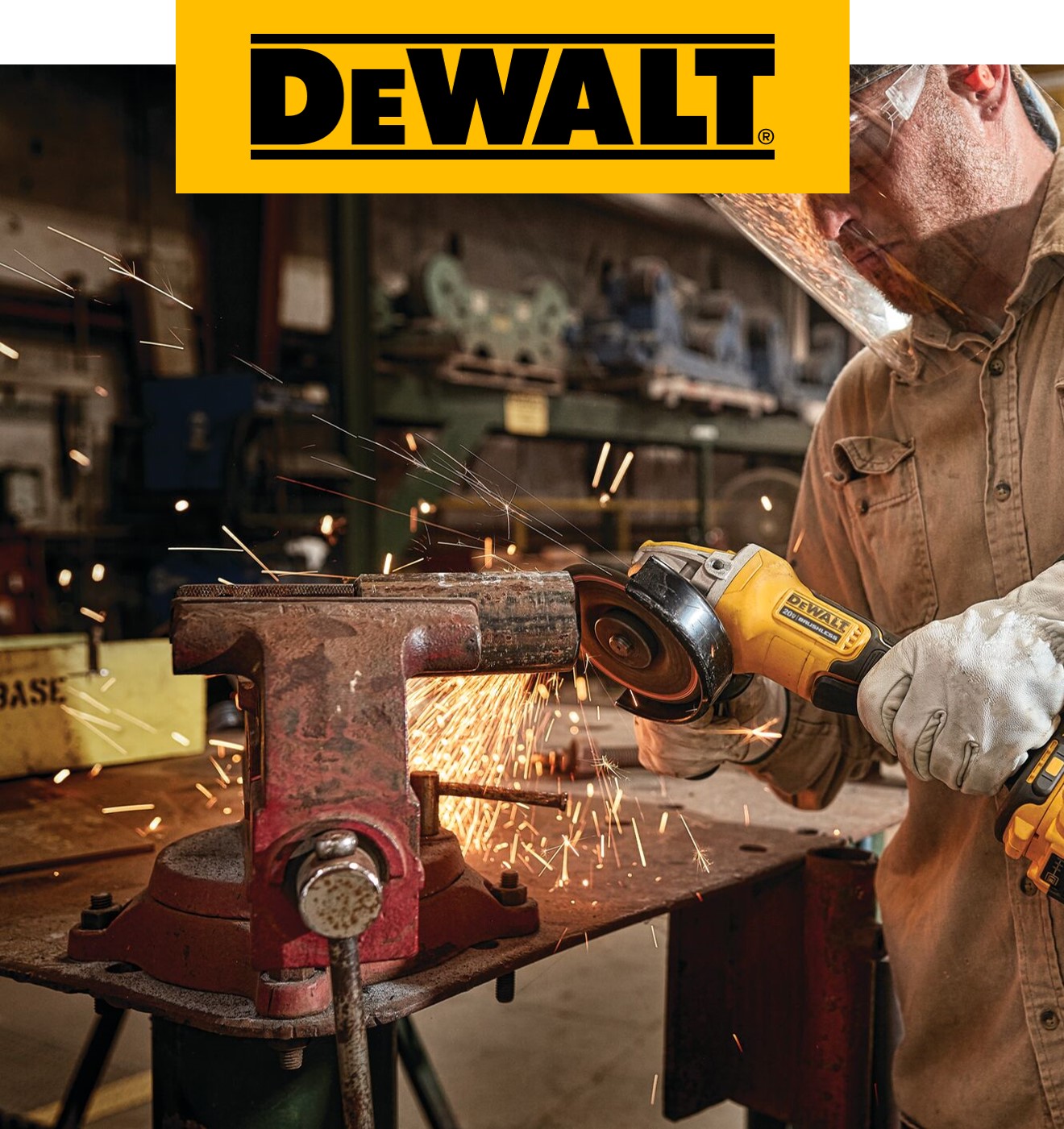

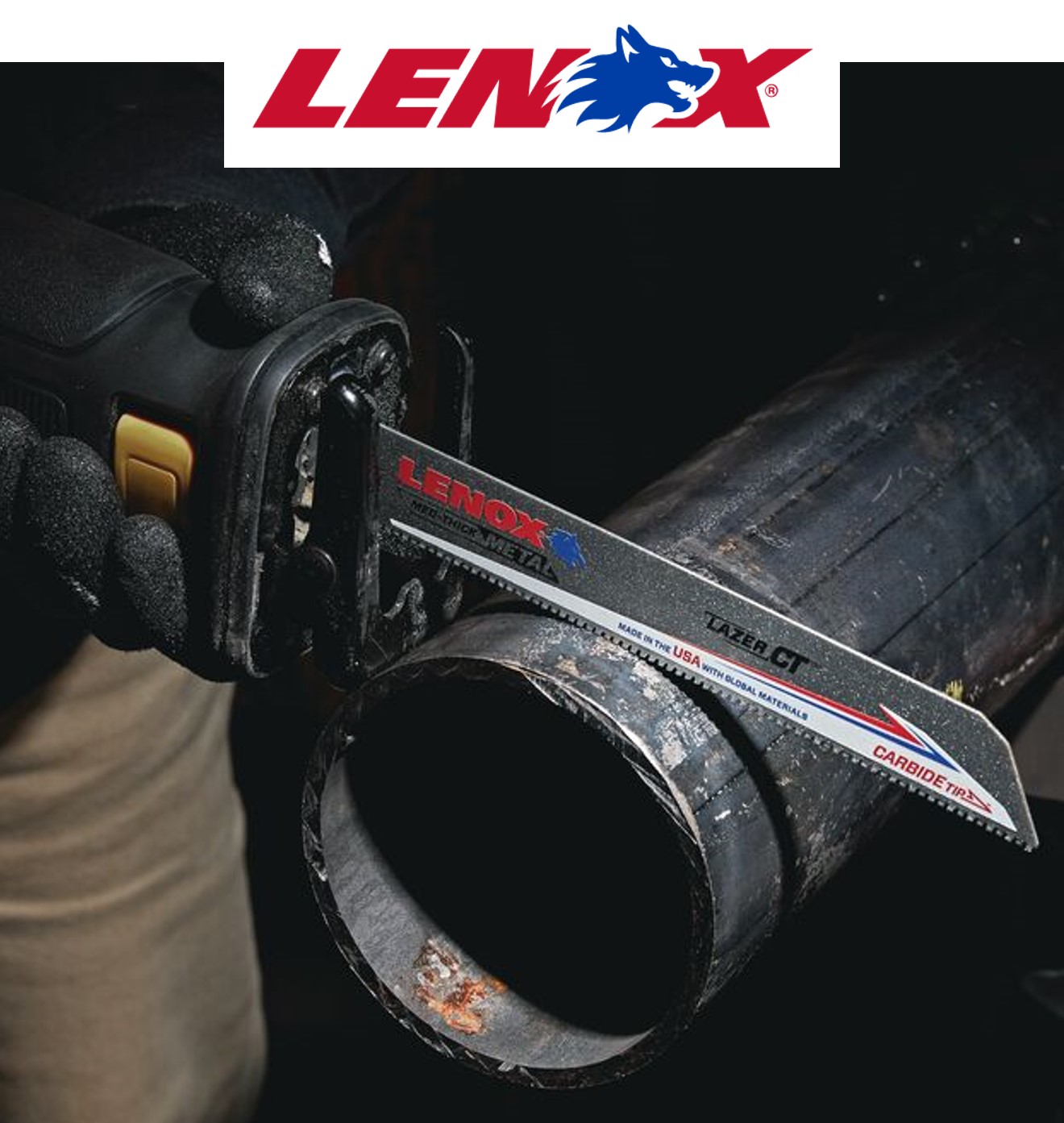

Featured at Richards:

See why Richards-Supply is your Local Industrial and Contractor Supplier!

OUR SERVICE SOLUTIONS

Richards Supply is your trusted independent source for industrial or contractor supplies and products in Texas. You will find a wide variety of in stock supplies and tools ready to be picked up in store, locally delivered by our fleet of trucks, or shipped out of our warehouse. Armed with industry veterans, and backed by an extensive network of premier suppliers, we help businesses, big and small, overcome challenges, increase productivity and improve efficiency. When you shop with us at RichardsSupply.com or come into any of our locations in Waco, Fort Worth, or Temple, Texas, you will get expert knowledge, easy ordering, quick delivery and a partner you can trust to get the job done.